Eco-balance inputs

Use of renewable energies

Over 80% of the energy used at Pfaffenhofen HQ comes from renewable energy sources. Since 2001, the entire heating, hot water and steam demands in the HiPP factory have been covered climate-neutrally by the use of biomass (wood chips). The electricity used comes from 100% CO2-neutral “green electricity” from hydroelectric power plants – without nuclear power. Since 2000, 6 solar projects have been built, which produce a total of 52,800 kWh/a from solar energy on a collector surface of 436 m². All organic waste goes to agricultural biogas plants. Every year, 2 million kWh of electricity is generated in this way.

With our organic farming we protect the soil and the groundwater

HiPP is the largest processor of biological raw materials worldwide. More than 6,000 farmers in many countries are involved in the production of organic fruit, organic vegetables and organic meat for HiPP.

Water – nature’s treasure and source of life

The shortage of clean drinking water is becoming an increasingly large problem. The times in which water was seen as a never-ending source are coming to an end. It therefore has to be saved as much as other finite resources. The industrial sector and private households are encouraged to use water-saving technology and to avoid unnecessary use.

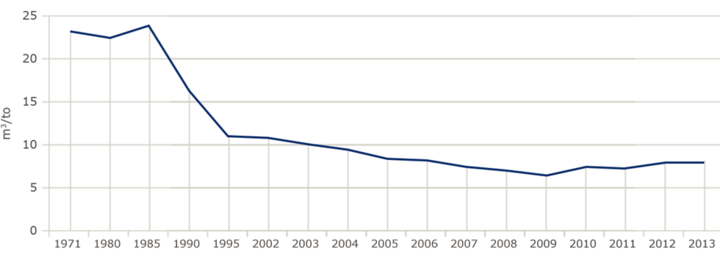

At HiPP, this necessity was recognised at an early stage and appropriate measures were introduced. The water usage was reduced from 22.8 m³ per produced ton in 1971 to 7.5 m³ per product ton in 2011. This resulted in optimised water circulation in production and circular flow in CIP cleansing, amongst other things. In general, HiPP makes sure that water is reused as much as possible.

HiPP well water

The factory in Pfaffenhofen has its own deep well. The Georg Hipp spring provides exclusive fresh water of the best, unspoiled quality. It is pure spring water that comes directly from the Alps and comes up from 154m below the HiPP premises.